Imagine if you were given a magical machine that could make anything you wanted; anything you dreamed; anything you desired. What would you make with it? Would you share it with others or keep it to yourself? Would you use it for fun or for work? Maybe you would use it to prototype your next great idea. In the past, you would have to pay huge sums in non-recurring engineering costs and wait a long time just to see if your prototype design would work or not. Well, things have changed because that magical machine exists today. It’s a 3D printer.

If someone gave you a 3D printer right here, right now, what would you make with it? Personally, I would use a 3D printer to make cool BeagleBone Black-powered toys for my kids… or a kegerator for my man cave! Maybe you would use it to make homes for the homeless, food for the hungry or clothes for those in need. Maybe you would use it to cure diseases, save the environment or invent the next best technological gadget. Anything’s possible with a 3D printer.

Can a 3D printer really do all this? Yes, it’s a printer that “prints” three-dimensional solid objects in a matter of hours instead of weeks. “Previously, I would design something, ship it to China for prototyping and wait weeks for it to come back just to find out the design was not quite right,” says Damon Domke, senior hardware/systems engineer for TI Sitara™ ARM® Processors who recently acquired a 3D printer. “Now, I just feed the printer my design, and within about an hour I can determine if my prototype needs any additional modifications.”

3D printers have actually been in existence for over 30 years and were so expensive that only major companies were able to buy them. Now, thanks to innovation and lower costs of goods, 3D printers are more widely available and affordable. 3D printers have gained popularity in the news by demonstrating the different ways they have been used to make clothing, bionic body parts, buildings and even food! It seems 3D printers have endless possibilities. This article by Gizmodo even shows the different material that can be used to create a variety of items.

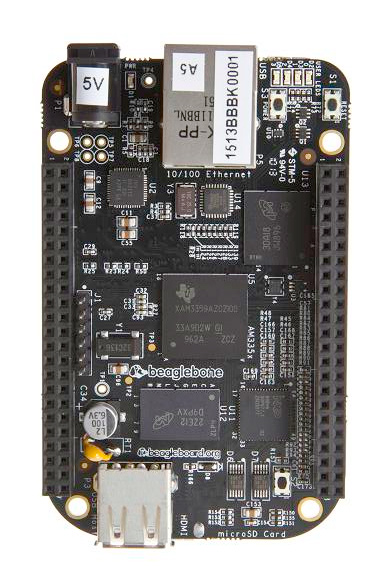

Up until now, a drawback to having your own 3D printer was that you needed to have a laptop dedicated to the printer as it consumed a lot of resources. However, by using a $45-BeagleBone Black open-source Linux computer with a 1-GHz Sitara AM3358 ARM Cortex™-A8 processor, 3D graphics coprocessor and 512MB of DDR memory, your designs can be processed on-board with no additional computer needed. Just connect BeagleBone Black to a BeBoPr or Replicape plug-in board, and you dedicate a corner of your office or lab to your own BeagleBone-based 3D printer station. Plus, since BeagleBone Black has Ethernet, you can share your printer station with friends around the world by having them send the printer design files from anywhere for immediate processing.

![]() BeagleBone Black

BeagleBone Black

Furthermore, with a 3D printer kit you can actually have your own 3D printer print a copy of itself right before your very eyes so you can give it to a family member (such as dear old dad – don’t forget him this month!).

As you can see, innovation opportunities are endless! Your ideas can become a reality. Need more inspiration? Check out our SpiderBot, a dancing robot powered by BeagleBone. The pink plastic parts of the dancing spider were created by a BeagleBone-based 3D printer.

Now that you are fully inspired, get your idea started by going to TI’s 3D printer page and see one way a 3D printer can be built. To check out another design, be sure to check out BeagleBone Black and BeBoPr plugin board!

![]()

BeBoPr Plug-in Board

What amazing innovations will you create? Leave a comment below letting me know.

Note: Since 3D printing is such a hot topic, we’ve decided to turn this blog into a summer series! Hot! Summer! Get it? Ha! Look out for our next blog in July that will focus on the value of an active, open-source community when creating a design with 3D printers. If you have a question, get stuck on something or just need a little more motivation the valuable members of Beagleboard.org and 3D printing communities will be there for you. Ask questions, gain knowledge, share your ideas and create a fan-base for your new design!

Alejandro Erives, Sitara ARM Processors Brand Manager, is anxiously awaiting the day 3D printers become self-aware. Good luck, John Connor.

BeagleBone Black

BeagleBone Black