In today’s Internet of Things (IoT) world, there is a multitude of new wireless connectivity applications entering the market each day, propelling the continuous gathering of sensors and interactions. From our smartphone reminding us it is time to leave for an event so that we will be on time, to our security system notifying us that no door is left open, we have a safety net of reminders helping us move throughout our day. These IoT devices typically have several hard-to-meet requirements. They need to operate on either Sub-1 GHz or 2.4 GHz RF bands to synchronize with already implemented systems. To encourage seamless, non-invasive sensing, you need a tiny form factor that can go unnoticed in your everyday life. This allows for the magical side of the IoT, where things around you just happen such as your home air conditioning kicks on when you are 20 minutes away, or your refrigerator adds milk to your shopping list because your daughter finished it with her afternoon snack. To accomplish this you need ultra-low power consumption and high integration, all in a tiny form factor. TI’s answer is the SimpleLink™ dual-band CC1350 wireless microcontroller (MCU), which is small enough to fit on your fingertip.

Save on size and power with the new CC1350 wireless MCU. The CC1350 solution is the latest device in the SimpleLink wireless MCU family released in early 2015. The CC1350 device is a highly integrated dual-band solution supporting Sub-1 GHz and Bluetooth® low energy on the same chip. Like the other devices in the SimpleLink family, it is designed with the same ultra-low power requirements in mind, along with market leading low power MCU and radios. The CC1350 wireless MCU also utilizes the sensor controller to handle analog and digital sensors in a low-power manner. It is designed to run autonomously when the rest of the system is in standby. Perfect for saving power in a sensor node network where power is your main concern. To learn more about enabling longer battery lifetimes read the “Taking Power to a new low with the SimpleLink ULP wireless MCU platform” blog post.

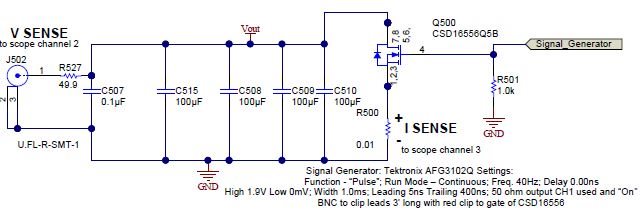

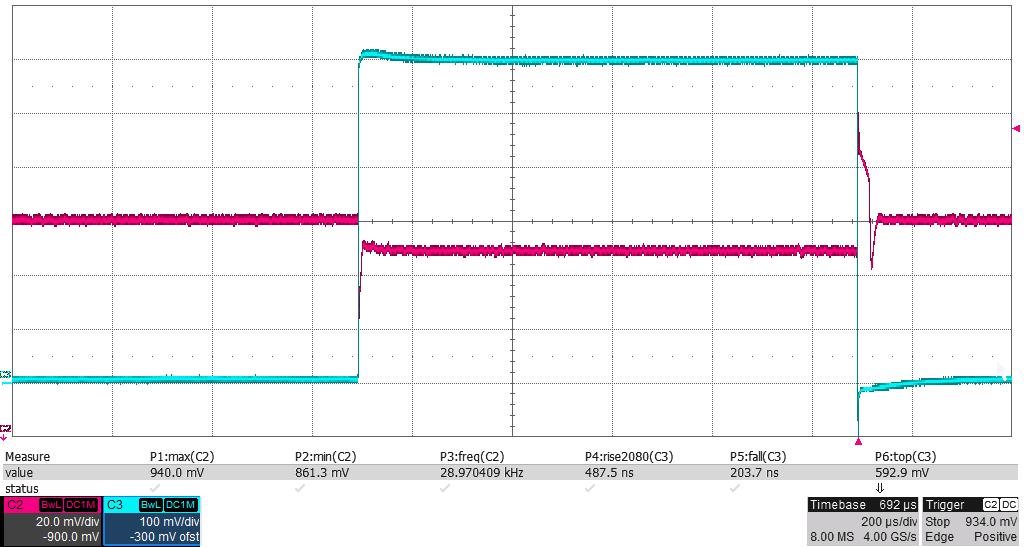

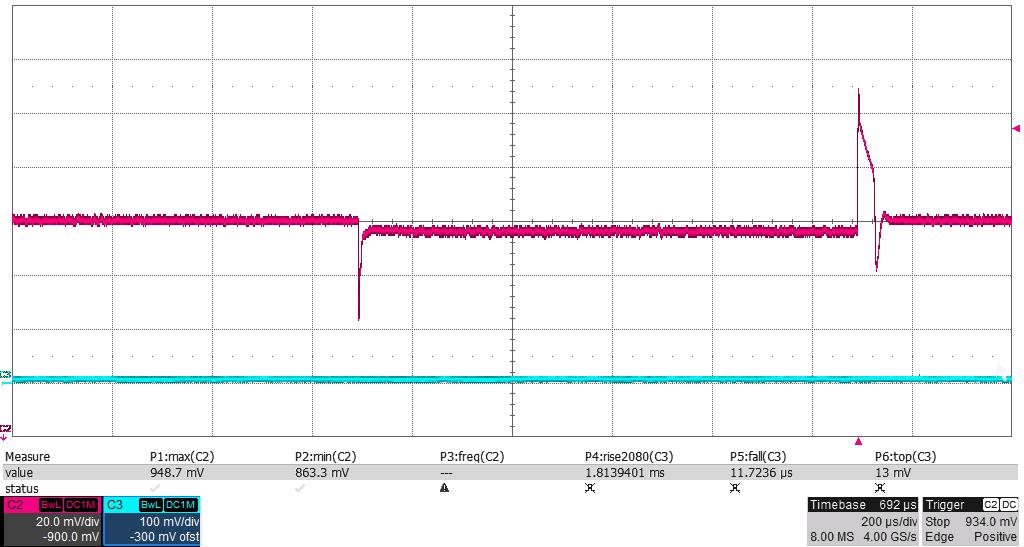

Figure 1: SimpleLink dual-band CC1350 wireless MCU power numbers

We have covered size and power, so what does dual-band bring to the table? How would you utilize Sub-1 GHz + Bluetooth low energy? Let’s talk about some of the use cases.

Let’s consider a house with a network of three smoke detectors. Typically there are detectors placed in different rooms, such as your kitchen, entry hallway and near the bedroom. The smoke detectors using Sub-1 GHz are connected in a simple star network to a gateway, enabled by the Sub-1 GHz long-range connection.

Installation/commissioning, maintenance and diagnostic of a Sub-1 GHz network: What if you want to add one more detector to your existing network? With Sub-1 GHz this can be tricky, as in some tightly packed neighborhoods you could accidently connect to your next door neighbor’s smoke detector network instead of your own. One way to avoid this is using a Bluetooth low energy connection to give credentials.

Figure 2: Commissioning

Using a smartphone as a remote display: What if you would like to quickly read diagnostics on your smoke detector network? Typically a smoke detector doesn’t have a display, but if each smoke detector had dual-band capability your cell phone or tablet becomes a display.

Beacon alerts: What if your daughter listens to music as she sleeps from her phone with headphones? Or maybe you watch the latest sports game at full volume in the game room. With dual-band functionality, you can get alerts on every Bluetooth low energy smartphone in your home warning you of impending danger.

Let’s consider another example, take a museum that has set up beacons on each exhibit. The beacons are there to notify the visitor of interesting facts about each exhibit, or send a wiki link with more information about a painting. Or is someone too close to a frame? A beacon alerts them to take a step back please.

Managing Bluetooth low energy beacon payloads: Updating a network of this size can be overwhelming - physically approaching each beacon for updates would be time consuming. Dual-band functionality makes this an easy task. The Sub-1 GHz link can be used to connect to the whole network of beacons and give the beacons new payload information.

Figure 3: Bluetooth low energy beacon network

Of course, these use cases are just the tip of the iceberg. How will you add Bluetooth low energy to your Sub-1 GHz network? Tell us more in the comments section!

To learn more:

- Read the CC1350 wireless MCU datasheet.

- Download the Sub-1 GHz long-range communication and smartphone connection for IoT applications white paper.

- Watch our video on why you should use Sub-1 GHz + Bluetooth low energy.

To get started quickly:

- Start evaluating with the CC1350 wireless MCU LaunchPad™ development kit.

- Order CC1350 wireless MCU samples.