Designers working on fast-switching data-acquisition systems often complain about random spikes, fluctuations, excessive noise or other kinds of unexpected voltage on their analog input channels. The common reason for these problems is impedance mismatching. When driving multiplexed systems with a high source impedance compared to the input impedance of the control system, you may see voltages from one scanned channel reflected on another scanned channel.

What if the source impedance and input impedance match but the unexpected voltage still persists?

Whether it is an industrial control system or any fast-switching data-acquisition system, more than one factor can cause an output voltage error when switching channels. However, for the purposes of this blog we’ll focus on one cause in particular, charge injection from the multiplexer. It is called charge injection because the charge within the device gets redistributed and can be pushed to the output when the device turns on and off.

In an industrial control system, a multiplexer toggling from one channel to the next can introduce a small charge on each channel. The lack of a path in the open channel for this charge to dissipate affects the voltage of the channel, which leads to an output voltage error. You might see an incorrect reading when scanning the analog input channels at a high rate.

Let’s explore two scenarios for a better understanding of charge injection and how it impacts the output voltage in a multiplexed system.

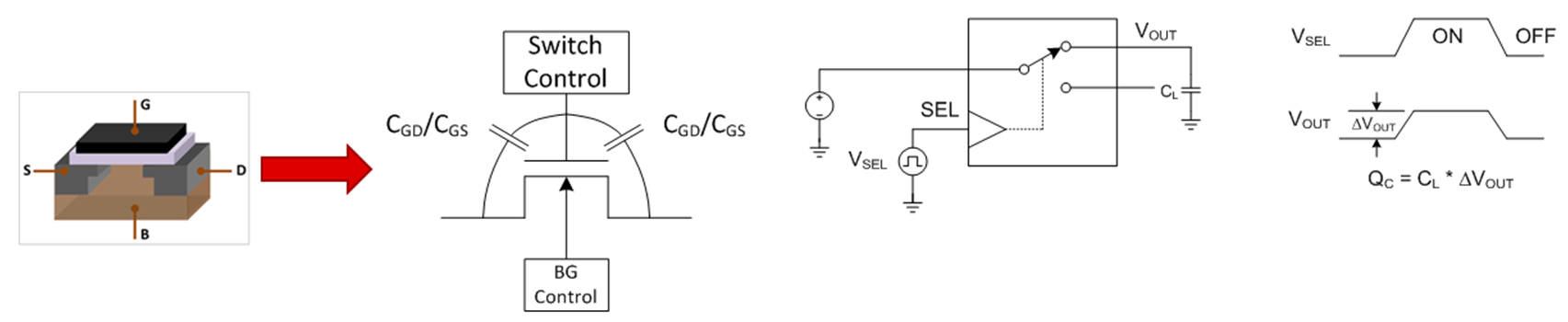

In the first scenario, a large load capacitance (CL) limits the bandwidth of the system. When the select pin (SEL) of the multiplexer toggles from low to high (or off to on, as shown in Figure 1), the gate of the MOSFET is subjected to a step voltage. This step voltage injects charge into the output of the switch through the parasitic gate-to-drain capacitance (CGD). The change in output voltage depends on the amount of charge injected (QC) and the load capacitance (CL).

Figure 1: Switch capacitance structure

Based on Equation 1, you can see that a large CL will minimize the effect of charge injection at the output of the multiplexer:

(∆VOUT = Qc / CL) (1)

This will limit the bandwidth of the input signal, however, as the multiplexer’s 3-dB cutoff frequency depends inversely on CL.

In the second scenario,we see what happens when sampling the switch output after the signal stabilizes before switching to the next channel. Unfortunately, this is not an option in industrial control systems that require a fast sampling frequency, so the best option is to choose a multiplexer with very low charge injection.

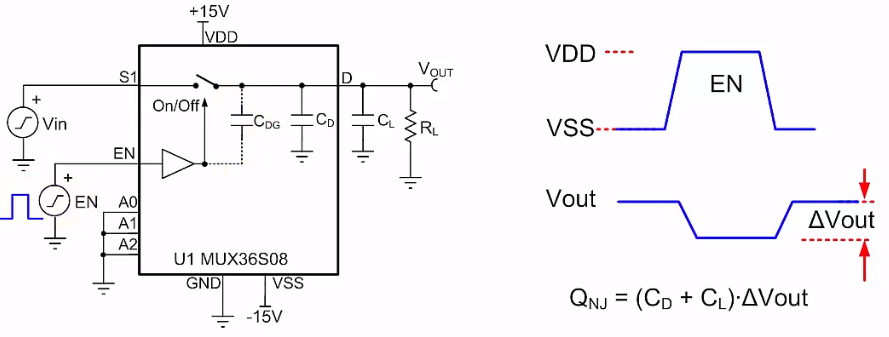

As shown in Figure 2, you can minimize the effect of charge injection if the internal parasitic capacitance that injects the error (CDG) is small. Typically, multiplexers with a lower on-capacitance have a lower charge injection.

Figure 2: TMUX6104 charge injection test setup

For better accuracy, not only should the charge injection be low, but it should also remain flat across the system’s input voltage range.

Since charge injection is a multiplexer parameter that varies with supply voltage, different source voltages may produce a nonlinear shift in output voltage readings - causing operational errors. In order to make the system more robust, a design engineer should pick a multiplexer that not only has very low charge injection but also remains flat across the application’s input voltage range.

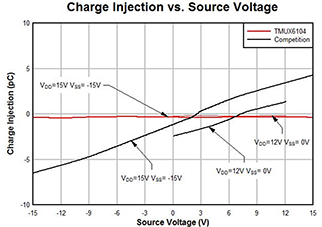

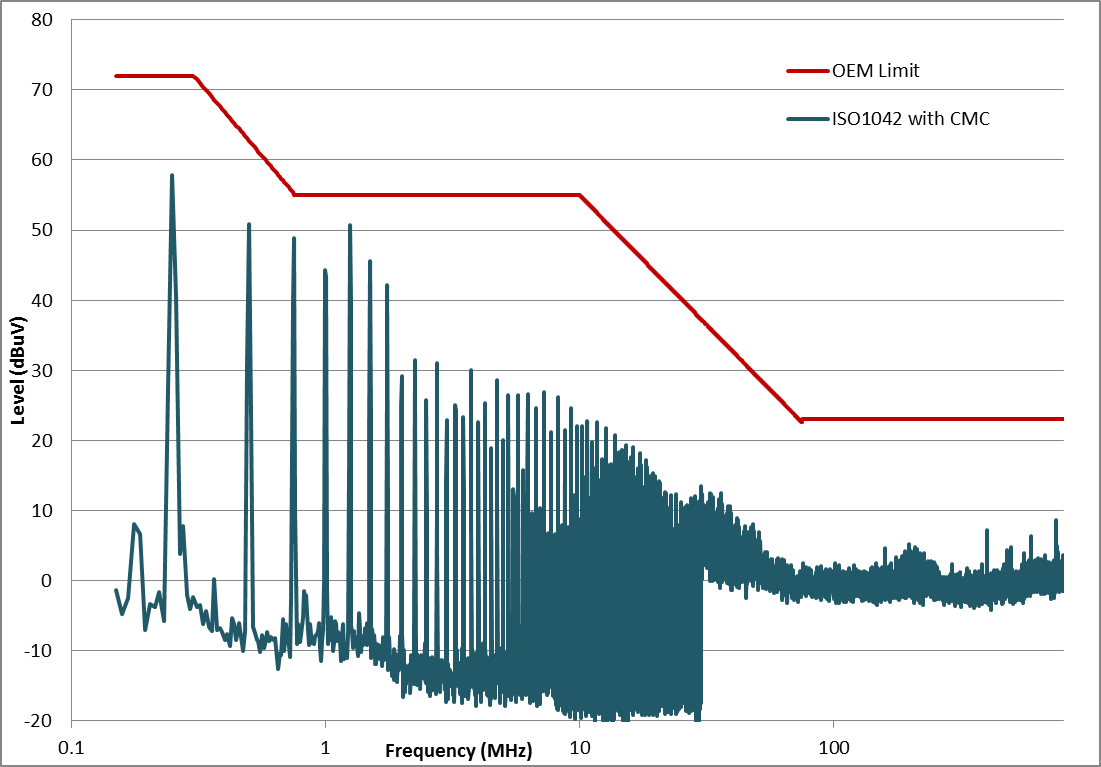

The TMUX6104 precision analog multiplexer uses special charge-injection cancellation circuitry that reduces the source-to-drain charge injection to as low as -0.35 pC at VSS = 0 V, and -0.41 pC in the full signal range.

Figure 3 is a charge-injection graph of the TMUX6104 across a supply voltage range of ±15 V. As you can see, when compared to a competing device, not only is the charge injection low but the variation of charge-injection performance across the input voltage range is minimal, making it a good fit for fast-switching industrial control systems.

Figure 3: TMUX6104 charge injection vs source voltage

Conclusion

Charge injection is a measurement of unwanted charge due to the redistribution voltage when a switch goes from on to the off state. It shows up as a voltage change introduced at the output of the switch when the channels are switched. For this reason, it is recommended that design engineers select a multiplexer with very low charge injection for a fast-switching data acquisition system.

Additional resources

- Download the TMUX6104

- Learn more about TI’s portfolio of switches & multiplexers

- Get online support in the TI E2E™ Community Interface forum