How RS-485 transceivers with OOK modulation simplify power line communication in building automation systems

How zero-drift Hall-effect current sensors improve system accuracy, reduce form factor and simplify design

<Content TBD>

An engineer’s guide to autonomous and collaborative industrial robots

Shrink your solution size with transformer-less ultrasonic ICs

Akeem Whitehead co-authored this article.

Sensors are everywhere – in our factories, homes, workplaces, even embedded within the objects we hold in our hands. With the integration of various technologies, it is becoming essential to design small.

Ultrasonic systems are no different. Integrated ultrasonic systems-on-chips with an H-bridge driver and high-performance analog receiver can reduce a printed circuit board (PCB) form factor as much as five times more than discrete solutions. Beyond that, direct-drive ultrasonic topologies can remove the need for a transformer, thus further reducing overall system size. This is particularly beneficial in factory automation, where entire sensor systems must fit within narrow screw housings.

In this technical article, we will explain the trade-offs between direct-drive and transformer-drive systems, including size and cost, detectable range performance, available transducer frequencies, and power consumption.

Find the right transformer-less ultrasonic sensor for your design

Learn the trade-offs of size, cost, power, transducer frequencies and range for your ultrasonic sensing design. View our portfolio of ultrasonic sensors. |

Size and cost

Ultrasonic analog front ends include an H-bridge driver for direct-drive solutions, or low-side drivers for transformer-drive solutions, as shown in figure 1. Ultrasonic transducers have varying requirements regarding the driver excitation voltage to generate a sufficient sound-pressure level, which is why the two driver types are available. The driver excitation voltage can range from a few volts to several hundred volts. For applications using open-face transducers in indoor environments, the low-voltage H-bridge driver type is common. For applications using closed-face transducers in outdoor environments, the transformer driver type is common. Although closed-face transducers can use an H-bridge driver, the maximum detectable range will be less compared to a transformer driver.

Figure 1: Ultrasonic sensing integrated solution block diagram

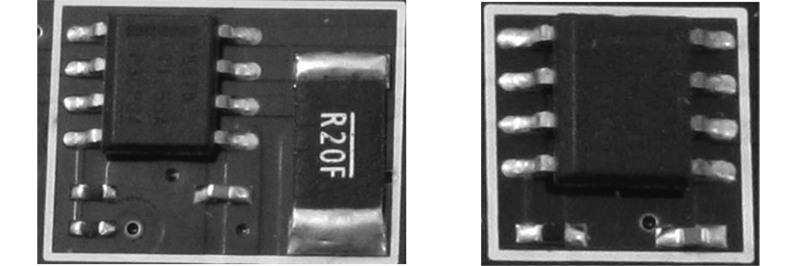

A direct-drive ultrasonic system can be used with a smaller charging capacitor, which reduces PCB size even further. Figure 2 compares the sizes of the TUSS4440 transformer-drive ultrasonic integrated circuit (IC) and TUSS4470 direct-drive ultrasonic IC.

Figure 2: TUSS4440 and TUS4470 reference designs to scale

Range performance

Two parameters to consider when deciding between a direct-drive ultrasonic approach or a transformer-drive ultrasonic approach is the minimum and the maximum detection ranges.

In the direct-drive approach enabled by the TUSS4470, the minimum detection range is hindered by a long ring decay time caused by the floating transducer resonance. In a transformer-drive approach, like the TUSS4440, introducing passive components in parallel to the transformer will reduce the ringing decay time. Figure 3 shows the decay times observed in various settings with the TUSS4440 and TUSS4470.

Figure 3: TUSS4440 and TUSS4470 ringing decay with a commonly used transducer

The maximum detection range directly corresponds to the number of pulses transmitted by the transducer and the voltage at which it is driven. A transformer-drive ultrasonic system enables distance detection from 5 to 10 m, due to its higher voltage drive, whereas direct drive is intended for systems <5 m. The TUSS4470 can sense objects beyond 5 m with its predrive mode even though it’s a direct-drive device. In this mode, introducing external field-effect transistors can increase the drive voltage and achieve longer distances. This enables applications such as asset tracking of cargo in large trucks or the detection of objects in large tanks.

Although the minimum and maximum detection ranges may vary, both the TUSS4440 and TUSS4470 integrate a wide-dynamic-range logarithmic amplifier that acts as automatic gain control, providing high sensitivity to weak echoes and preventing saturation of already strong echoes. This feature enables both devices to detect a wide variety of targets – whether they be small or large, close or far.

Transducer frequencies

Transducer frequencies determine the range and resolution of an ultrasonic sensor. The higher the transducer frequency, the higher the resolution will be (as little as in the millimeter range). However, higher frequencies attenuate faster in air, leading to a lower sensing range.

Direct-drive ultrasonic systems can tolerate high frequencies up to 1 MHz due to the built-in shoot-through current protection of the H-bridge driver circuit. Transformer-drive systems are limited to 400 kHz due to the lagging effects of the transformer’s secondary inductance. Liquid-level sensing applications often use higher frequencies (1 MHz), since attenuation is not as strong through liquid as it is through air.

Power consumption

In a direct-drive approach, the H-bridge driver is current-limited to 50 mA. The low driver current does not cause the main supply to droop, so you can use a smaller charge capacitor at the high-side driver reference for the H-bridge circuit. In the case of TUSS4440 and TUSS4470 devices, the VDRV pin is used as the driver voltage reference.

For a transformer-drive ultrasonic system, a large sink current of up to 500 mA during drive requires a large charge capacitor to provide the bulk of the drive current. This charge capacitor must recharge between each burst cycle, which adds delay between burst iterations.

The TUSS4440 and TUS4470 GUI includes a power budget calculator (Figure 4) to help estimate current consumption.

Figure 4: The TUSS4440 and TUS4470 EVM GUI power budget calculator tool

In summary, direct-drive ultrasonic systems enabled by the TUSS4470 provide many benefits, such as reducing PCB form factor and lowering the total system cost of an ultrasonic system. However, if more stringent minimum and maximum ranging performance is required, you should consider a transformer-drive solution like the TUSS4440.

For more information on our ultrasonic portfolio, visit ti.com/ultrasonic.

Additional resources

- For more information on how to reduce ringing time, see section 2.8 of the application report, “Ultrasonic Sensing Basics.”

- To learn more about logarithmic amplifiers, read the application report, “Logarithmic Amplifier for Ultrasonic Sensor Signal Conditioning.”

- Check out the ultrasonic sensing FAQ on the TI E2E™ forums for a list of commonly asked questions.

Understanding and managing buck regulator output ripple

Dan Tooth co-authored this technical article

Your new design needs to fit twice as much into half the space and cost nothing – sound familiar? You selected the smallest point-of-load regulator and generated the tightest layout you could with the most cost-effective passive components. So far so good. But then you look at the output ripple on your critical rails and it’s not what you expected. What’s going on?

Let’s start by understanding what makes up the output ripple on a buck DC/DC regulator. It is a composite waveform. Traditionally only the three dominant elements shown in Figure 1 have been considered:

- A triangular wave generated by applying the inductor current ramp across the equivalent series resistance (ESR) of the output capacitors. A 22-µF X5R ceramic capacitor may have an ESR of only 2 mΩ. Considering an inductor peak-to-peak current ripple of 1 A, the ESR ripple is 2 mV (less if you’re using multiple parallel capacitors).

- A pseudo-sinusoidal component due to output capacitance. For the same output capacitor and ripple current as in the bullet point above, the capacitive ripple will be around 8 mV (less for multiple parallel output capacitors).

- A square component generated across the output capacitor equivalent series inductance (ESL). For a 22-µF X5R capacitor, the ESL is around 0.5 nH, which generates a ripple of about 2 mV.

Figure 1: Typical output ripple waveforms

However, what you measure has spikes on the edges and a higher square-wave content that changes polarity when you reverse the inductor shown in Figure 2:

Figure 2: Measured output ripple

What has caused these undesirable components? And more importantly, what can you do about it?

Spikes

When you selected your inductor, the self-resonant frequency (SRF) was above your regulator switching frequency, so all was good. Let’s re-look at that – the inductor has an SRF because it has a parallel parasitic capacitance. Applying the fast edge of the switching voltage to the parasitic capacitance generates a large current spike through the capacitor, which in turn generates a large voltage spike across the ESL of the output capacitor (see Equation 1):

To reduce this spike:

- Select an inductor with a smaller parasitic capacitance. Look for the highest SRF value for the inductance and rating you need. Lower inductances tend to have lower parasitic capacitance (as do lower current ratings), so don’t over-specify the inductance or current rating.

- Reduce the output capacitance ESL. Choose the smallest capacitor package size that meets your output capacitance requirements. Using multiple smaller capacitors in parallel means the package size (and hence the ESL) of each capacitor can be smaller, while having inductors in parallel will also reduce the total ESL.

- Reduce the transient voltages (dV/dt) of the switch node (increase the value of t). Some regulators may allow direct control of the switch-node edge, but more often you may be able to place a small resistor in series with the bootstrap capacitor to slow the edge. This can impact efficiency, so the first two options are preferable.

Square wave

Let’s say that you selected a cost-effective, unshielded inductor. The magnetic field from an unshielded (or resin-shielded inductor) can spread beyond the physical body of the component. The simulation plots in Figure 3 show the field for an unshielded open drum inductor and a fully shielded molded inductor.

Figure 3: Magnetic field for unshielded drum and shielded molded inductors (Source: Courtesy of Coilcraft)

· Select a shielded inductor to reduce the leakage flux that generates this coupling. If you’re using unshielded or semi-shielded inductors, selecting an inductor that is larger in the x-y dimension but has a lower profile will reduce the airgap height and hence the fringing flux.

· Reduce the output capacitance ESL as described above.

· Don’t position the output capacitors and tracking directly next to the inductor, where the field is highest. Where space is critical, consider placing the inductor on the opposite side of the board to the rest of the regulator circuit in a clamshell construction. This moves the output capacitors away from the plane of the inductor where the magnetic field is strongest.

· Read the Analog Design Journal article, “Select inductors for buck converters to get optimum efficiency and reliability.”

· Download the application reports, “Output Ripple Voltage for Buck Switching Regulator” and “Space Optimized, ‘Clam-Shell’ Layout for Step-Down DC/DC Converters.”

Stay ahead of the energy storage and solar game with bidirectional PFC and hybrid inverter solutions

When to choose a DSP for processing voice commands

Tim Simerly co-authored this technical article

In a twist of irony, the massive technological expansion of the telephone system – which led to the creation of the internet and all of its features and benefits – enables millions of simultaneous transactions without requiring a single human conversation. Yet in this efficiency-focused 21st century world, the plethora of voice-activated smart home devices confirms that live speech has become the de facto medium for smart home virtual assistants. Consumers can still pick up a remote and press the volume button; they can use their phones to place an online order and their hands to flip a light switch. But it seems clear that voice as a user interface is here to stay, and real-time signal processing is the key enabler of this modality.

Real-time signal processing consists of converting and processing analog signals by performing complex math operations. Digital signal processors (DSPs) are the most efficient way to process math in real time. While all processors can perform real-time signal processing math calculations, the DSP architecture by design ensures that these processes will happen faster, with less energy and less generated heat than more generic processor architectures.

Voice as the user interface – a new era in speech processing

Read the white paper here |

Voice capture and speech recognition devices and applications are not new. However, properly recognizing and capturing speech amid television noise or conversations requires far more processing than simply capturing speech from a single microphone in a device that’s close by and in a relatively quiet environment.

Key design factors in a smart speaker-like solution include accurate voice discernment (given the user’s distance from the speaker), the amount of ambient noise in the area and the need for two-way speaker conversation. For near-field processing, a relatively simple system of three or fewer microphones, wake word detection, fixed beamforming and signal-noise reduction may be all that’s required. It is possible to execute such a configuration easily on a microcontroller (MCU) within a low-power, memory and cost footprint.

However, depending on the application, the consumer may expect to command the smart speaker from both the near-field and far-field, and to have the speaker accurately discern their speech over noises from sources such as TVs, smartphones, background conversations, wind and other ambient sounds. To be effective, this complex environment typically requires between four and eight microphones that in turn require adaptive beamforming and adaptive spectral noise reduction (ASNR) algorithms, along with multisourcing selection functionality. This significantly increases the real-time signal processing complexity.

Applications such as video doorbells expand the processing complexity one step further, requiring process-intensive acoustic echo cancellation (AEC) to improve the user experience. AEC, along with beamforming and ASNR, tips the scales in terms of exceeding MCU efficiency, but DSPs can effectively process voice as a user interface engine.

DSPs continue to be the most efficient means of processing real-time audio commands, especially amid the ambient sounds and noises commonly present in our environment. Just as in a smart home interface where consumers prefer using their voice because it’s the most efficient, DSPs are preferable for far-field, four-or-more microphone, or two-way-speaker smart home solutions where size, power, performance and cost are key metrics.

Additional resources:

- Check out this Audio Preprocessing System Reference Design for Voice-Based Applications

- Learn more about all of TI’s audio and media processors.

What type of ESD protection does your MOSFET include?

Power metal-oxide semiconductor field-effect transistors (MOSFETs) use a thin oxide to isolate the gate electrode from the active area of the transistor. Much like the MOSFET structures used in the fabrication of microprocessors, a power MOSFET gate oxide is just as susceptible to damage from electrostatic discharge (ESD) as its tinier counterparts. ESD may cause catastrophic failure (such as gate-oxide breakdown) or non-catastrophic damage.

Some discrete power MOSFETs and power-block MOSFETs include integrated ESD protection structures to prevent unwanted MOSFET failures caused by ESD. In this article, I’ll explain the differences between the ESD structures used in power MOSFETs and look at design considerations for these devices.

ESD structures used in TI MOSFETs

First, let’s look at the three protection categories into which discrete power MOSFETs and power-block MOSFETs fall: no ESD protection, single-ended ESD protection and back-to-back ESD protection.

No ESD protection

The first category is self-explanatory and makes up the bulk of power MOSFET and power-block MOSFET products offered by TI and other vendors. Although these MOSFETs do not have an integrated gate ESD structure, they still have an inherent ESD capability that can range from as low as 150 V to as high as 3,000 V. The ESD capability is related to device density and charge; as such, larger die sizes have higher ESD capabilities.

You should always confirm that the MOSFET’s ESD capability meets the requirements in your application; if it does not, consider adding external ESD protection. Figure 1 illustrates the schematic symbols for TI N-channel and P-channel MOSFETs with no integrated ESD protection.

Figure 1: MOSFETs with no ESD protection: N-channel (a); and P-channel (b)

Single-ended ESD protection

The second category includes N-channel and P-channel MOSFETs with an integrated, single-ended ESD protection diode from gate to source. Devices in this category can achieve ESD ratings >4,000 V. Historically, ESD protection of a power MOSFET gate resulted in higher gate leakage current. However, some devices, including TI’s CSD25480F3, can now achieve industry-leading leakage specifications as low as 25 nA; these are better specifications than devices with no gate ESD!

Because of their low gate leakage, TI MOSFETs are a good fit for battery-powered applications where standby power and runtime are critical. You must carefully evaluate operating conditions to ensure that the ESD diode is not forward-biased, as it will conduct current. If forward-biasing is unavoidable, then I recommend including an external, current-limiting gate resistor in the circuit. Figure 2 shows N-channel and P-channel schematic symbols with the single-ended ESD protection diode highlighted.

Figure 2: MOSFETs with single-ended ESD protection: N-channel (a); and P-channel (b)

Back-to-back ESD protection

The final category includes N-channel and P-channel MOSFETs with a back-to-back ESD protection structure. The ESD capability of these devices ranges from 400 V up to 3,250 V. There is no need to worry about forward-biasing the back-to-back ESD structure, but these MOSFETs have higher gate leakage current than MOSFETs with single-ended ESD protection. This higher gate leakage may be a drawback in battery-powered applications. Figure 3 shows N-channel and P-channel schematic symbols with back-to-back ESD protection highlighted.

Figure 3: MOSFETs with back-to-back ESD protection: N-channel (a); and P-channel (b)

Examples of ESD ratings and leakage current for TI MOSFETs

Table 1 lists some examples of the human body model (HBM) and charged device model (CDM) ESD ratings and maximum gate leakage current for N-channel and P-channel TI MOSFETs in each category.

Part number | N-channel or P-channel | ESD protection category | HBM ESD rating (V) | CDM ESD rating (V) | Maximum IGSS (nA) |

N | None | 600 | 2,000 | 100 | |

P | None | 250 | 1,500 | -100 | |

N | Single-ended | 7,000 | 2,000 | 50 | |

P | Single-ended | 4,000 | 1,000 | -50 | |

N | Back-to-back | 3,000 | 2,000 | 5,000 | |

P | Back-to-back | 2,000 | 2,000 | 10,000 |

Table 1: Examples of TI MOSFET ratings for ESD protection categories

Conclusion

Discrete power MOSFETs and power-block MOSFETs offer different categories of gate ESD protection. Each category has trade-offs in terms of ESD protection levels and gate leakage current. Knowing these trade-offs can help you make informed decisions when selecting a MOSFET for your application.

As a helpful reminder, look for the schematic illustration, which depicts the type of ESD protection included in a particular device, on page 1 of TI MOSFET and power-block data sheets.

Additional resources

- Visit the TI MOSFET support and training center.

- Read the application report, “Electrostatic Discharge (ESD).”

5 questions to ask when designing with rechargeable batteries for personal care products

Beauty and personal care products have traditionally been designed with a traditional AC power supply. Therefore, every time consumers use such products, they need to be close to the wall, and any movement and power is restrained by the length of the electrical cord. As modern electronics have evolved, consumers now expect to be able to use personal care products such as a shavers, epilators, muscle massagers, electric toothbrushes and face-cleansing products without being tethered to a wall socket.

To meet consumer demands, today’s personal care products, like those shown in Figure 1, include a primary battery, a small DC motor and a rotating accessory. It remains a challenge to ensure a battery life of more than one hour for these applications, however, particularly when they rely on AA or AAA batteries. To help extend battery life and flexibility for consumers, lithium-ion (Li-ion) batteries can help make personal care products more portable.

Figure 1: Examples of Li-ion battery-powered personal care products

Li-ion batteries offer high power density in addition to being lightweight and small. It’s common for design engineers to either choose a single- or two-cell Li-ion battery configuration for the design of personal care products, but there are trade-offs between the two options.

Here are five questions to ask when choosing a charger integrated circuit (IC) for a Li-ion battery-charger design.

1. Do you want to charge the device from USB or all possible power sources?

You’ve likely had the experience where you simply cannot find the dedicated adapter you need to charge a particular product. Between your smartphone, smartwatch, notebook, shaver, camera and whatever else you’re traveling with, it seems that each device requires a different adapter to charge.

Li-ion batteries charger ICs can support charging through various adapters and a wide voltage range, from 4 V to 17 V. Keep in mind that charger ICs with anything lower than a 20-V input will require an external overvoltage protection IC to prevent electrical surges.

With new homes, airports and hotels now supporting embedded USB charging ports, universal charging from these adapters is an important design choice, and will aid in enhancing the convenience of using the product.

2. How much do you need – or want – to simplify your design?

Hardware and software implementation can be a cumbersome and costly task – R&D time is precious. Choosing a charger IC for easy layout on two-layer printed circuit board (PCBs) can help along with autonomous charging, precharge, constant current(CC) fast charge and constant-voltage(CV) charging to termination. A two-layer design also makes it easier to debug the hardware. If you choose a stand-alone IC, all charge voltage and current are preset by external resistors. This means you will not need to program your charger IC with software.

3. How important is fast-charging capability and an extended battery life?

Time is precious, and consumers have little patience to charge their devices longer than a few minutes before use. Ideally, full charging should be complete within an hour.

To enable quick charging for immediate use of the product, the charger IC needs to do high-current charging safely and accurately. In addition, customers should be able to recharge the battery more than 500 times and have the battery still deliver at the same load current as it did when it was new for many months or years, depending on how often it is used.

Li-ion battery chargers need to have highly accurate charge current and voltage control across different conditions (listed in the parametric data sheet) to avoid charging higher than the battery specification voltage in any condition. Every time the product is recharged, the battery terminal voltage is regulated precisely to a voltage such as 4.20 V (see Figure 2). Overcharging will decrease the number of recharge cycle with battery capacity loss.

Figure 2: Li-ion battery recharge cycles and cell capacity loss caused by a higher-than-specified termination voltage (Source: “Factors that affect cycle-life and possible degradation mechanisms of

a Li-ion cell based on LiCoO2”)

4. How long does the shelf-life of the product need to be?

When the product is made with the battery only charged to 50%, it will typically take about three to six months to reach the hands of the consumer. Products with the battery connected will start losing battery life while in transit. Low quiescent current (IQ) in the charger is essential to support instant use by the consumer before a recharge is required.

5. What protection features are required?

Chargers for Li-ion batteries typically have multiple control loops. Those are dedicated to protecting the charger IC and battery during charging, such as over voltage protection, over current protection , pin open/short detection to prevent battery overcharge, , battery temperature sensing control, charger IC thermal regulation and thermal shutdown, etc. Accurately monitoring battery temperature and setting a pin to open for quick protection in any unexpected cases is something to consider in the design.

To help design engineers address many of these challenges, TI’s BQ25306 family of battery chargers is designed for universal charging of 1 cell in series (1s) and 2 cell in series (2s) batteries with a 4-V to 17-V input voltage and 28 V of protection for possible surges. With an external resistor setup, the BQ25306 family charges the battery automatically, and its 3-mm-by-3-mm quad flat no-lead package is small enough to accommodate a two-layer PCB design, as shown in Figure 3.

Figure 3: BQ25306 family block diagram

For more information on how to incorporate the BQ25306 into your next design of a personal care product, engage with our engineering community through the TI E2E™ support forum or see the additional resources below.

Additional resources

- Review the BQ25306 evaluation module.

- Read the article, “When to use rechargeable batteries in small battery applications.”

Universal and fast charging – a future trend for battery-powered applications

Today’s “always-on” consumer wants to charge their portable electronics wherever they are. For example, it’s common to see travelers charging their cellphones, laptops and headphones while waiting to board a flight or hop on a train. But when there are different charging methods for each device, these consumers must carry different adapters, and it can become quite a hassle to remember each adapter for each device (see Figure 1). For engineers to help minimize this hassle, their battery charging system designs must support charging from various input sources.

Why consider USB Type-C PD charging?

Designing a single-chip charger integrated circuit (IC) to charge multiple battery-powered devices with different configurations and different input-voltage ranges can be a complicated process, since classic adapters are not compatible with all battery-powered devices and traditional USB adapters are limited to 5-15 W, limiting the portable battery-powered devices they will support.

USB Type-C™ Power Delivery (USB PD) offers a useful alternative for fast and efficient charging of a wide range of applications, as illustrated in Figure 2. The output voltage range of USB PD is adjustable for different battery-powered devices with different battery configurations to utilize 5 W to 100 W (20 V / 5 A) power spectrum of USB PD.

Figure 1: Charging with different input sources and adapters

Figure 2: Universal and fast charging enabled by USB PD

Expanding on the above example of a traveler charging one or more devices, the best-case situation given their potentially limited access to a power supply is that their devices will quickly charge to full battery capacity, and that the battery will last for an extended period of time once charged. Even if they only have a quick 15-minute layover to recharge a device, that should be enough to extend battery operation for hours.

Thus, to meet consumer expectations, design engineers are looking for solutions that can:

- Simplify their designs while enabling universal charging – the ability to charge multiple battery-powered devices with different configurations (1 cell in series [s] to 4s) and different input voltages.

- Extend battery run times and use the maximum battery capacity to enable the best consumer experience.

- Charge efficiently while reducing thermal dissipation to minimize power loss within the charger IC.

- Protect the input adapter, battery and system from a cascade failure.

TI’s new family of integrated buck-boost battery-charger ICs, including the BQ25790 and BQ25792, leverage USB PD input for improved flexibility in charging 1S – 4S batteries across an input-voltage range of 3.6 V to 24 V. With integrated components, these buck-boost chargers give you the freedom to choose whether a single-charger IC is a better design choice for compact, size-constrained battery-powered devices like cell phones, laptops, Bluetooth headsets or medical equipment vs. designing with multiple power stages that need either boosting up or bucking down to keep the application within a safe operating voltage range.

The BQ25790 and BQ25792 leverage an ultra-low power consumption charger IC to extend the battery’s run time during operation and to conserve as much battery power as possible when the application is not in use. In addition to ultra-low power consumption, the chargers come with a top-off timer that enables extra charging on top of a normal charge cycle, ensuring that the battery can charge to its maximum capacity (see Table 1).

Parameter | Programmability | Resolution | Default |

Charge voltage | 3 V-18.8 V | 10 mV | 4.2 V (1 cell in series [s]), 8.4 V (2s), 12.6 V (3s), 16.8 V (4s) |

Charge current | 50 mA-5 A | 10 mA | 2 A (1s), 2 A (2s), 1 A (3s), 1 A (4s) |

On-the-go (OTG) voltage | 2.8 V-22 V | 10 mV | 5 V |

OTG current | 120 mA-3.32 A | 40 mA | 3 A |

Pre-charge current | 40 mA-2 A | 40 mA | 120 mA |

Termination current | 40 mA-1 A | 40 mA | 200 mA |

Top-off timer | Disabled, 15 minutes, 30 minutes, 45 minutes | ||

Table 1: Included programmable features on the BQ25790 and BQ25792

For power designs that require a long run time, short and efficient charging, and a compact design, USB PD charging offers flexibility to charge a wide range of applications while keeping bill of materials low and shrinking total solution size. To learn more about designing with power density and low quiescent current in mind, check out the additional resources below.

Additional resources

- Read the technical article, “Small chargers pack a powerful punch: combining buck-boost and USB Type C™ power delivery for maximum power delivery.”

- Watch the video, “What could you achieve with universal and fast charging?”

Maximize power density with buck-boost charging and USB Type C™ Power Delivery

The buck-boost charger has become increasingly popular in recent years given its ability to charge a battery from nearly any input source, regardless of whether the input voltage is higher or lower than the battery voltage.

One critical benefit of the widespread adoption of USB Type-C is a realistic path to a universal adapter and corresponding e-waste reduction. Although the USB Type-C connector is unified, adapter power ratings and voltages still have large variations, including the legacy 5-V USB adapter and USB PD adapters capable of providing a voltage range from 5 V to 20 V. In addition, different portable devices might have different numbers of cell batteries inside. These variabilities in input voltage and battery voltage require a buck-boost topology for battery-charger integrated circuits (ICs). The high power density buck-boost chargers should not only integrate the general charging functional blocks, but also integrate the additional components in the USB PD charging system, such as load switches and DC/DC converters, to streamline system design, reduce bill-of-materials (BOM) cost and keep the overall solution size small. Figure 1 shows a system block diagram for a USB PD charging solution.

Figure 1. Block diagram for a USB PD charging solution.

In order to support the USB On-the-Go (OTG) specification, one DC/DC converter discharges the battery to build up a regulated voltage at VBUS and power external devices when the adapter is not present. If the USB Type-C port requires fast role swap (FRS), the DC/DC converter has to be enabled and kept on standby all the time, even if an adapter is plugged into the USB Type-C port. When the adapter is disconnected, the back-to-back MOSFETs in the discharging power path turn on, passing the U3 output voltage to VBUS and holding on the VBUS voltage. Keeping the DC/DC converter always on actually causes extra quiescent current loss for the entire system.

The fully integrated buck-boost charger shown in Figure 2 can simplify the system-level design of a USB PD charging solution. First, the input current sensing is integrated into the charge. With this sensed input current, the charger provides the input current regulation and input overcurrent protection to avoid adapter overload. As part of the input overvoltage and overcurrent protection circuit, the control logic and driving circuitry for the external back-to-back MOSFETs are also integrated into the charger. These features make it possible to eliminate the unit that supports input power-path management and input current sensing from the block diagram.

Implementing the bidirectional operation of the four FETs’ buck-boost converter allows the charger to support OTG mode itself. When the adapter is present, the charger operates in forward charging mode with power flow from VBUS to the battery. When the adapter is disconnected, the power flow reverses from the battery to VBUS. The OTG mode output voltage at VBUS covers the full USB PD voltage range, from 2.8 V to 22 V with a 10-mV programmable step size, which is compatible with the USB PD 3.0 specification.

Figure 2. The proposed fully integrated buck-boost charger.

In order to support FRS for the USB Type-C port, this integrated buck-boost charger implements a novel backup mode. In this context, backup mode refers to an ultra-fast transition for the buck-boost charger from forward charging mode to reverse OTG mode without the bus voltage crashing. Looking at the application diagram in Figure 3, the adapter connects at the USB port, powering the system and charging the battery through the buck-boost power stage. At the same time, the adapter could power accessories from the charger’s PMID output. When the adapter is disconnected, the battery’s internal FET can still power the system; however, the accessories at PMID might lose power.

With backup mode enabled, the charger is able to monitor the VBUS voltage; the VBUS voltage dropping lower than the preset threshold indicates the adapter’s removal. Once it detects a removal, the charger shifts from forward charging mode to OTG mode with minimal delay time, discharges the battery to regulate the VBUS voltage, and achieves FRS by itself. When the adapter is unplugged, the sources to power the system and accessories can switch from the adapter to the battery seamlessly, making it possible to eliminate the DC/DC converter for OTG mode and FRS from the block diagram.

Figure 4 shows the tested waveforms of the charger backup mode for FRS. A 9-V adapter is connected at USB1 as the input power. VBUS is shorted to the adapter by turning on ACFET1-RBFET1. Assume that there is a 1-A accessory current at PMID and a 1-A charging current at BAT. When the 9-V adapter voltage (VAC) is gone, the PMID and VBUS can still be regulated at 5 V to continuously power the 1-A PMID load.

Figure 3. USB Type-C FRS realized by single buck-boost charger.

Figure 4. Buck-boost charger FRS from VBUS sink to VBUS source.

All of the features described above help simplify the system-level design of a USB PD charging solution, and TI has implemented in our latest buck-boost chargers, the BQ25790 and BQ25792. These chargers support one cell in series (1s) to 4s battery charging from a 3.6-V to 24-V input voltage, covering the full USB PD input voltage range.

These features are available in a 2.9-mm-by-3.3-mm wafer chip-scale package or a 4-mm-by-4-mm quad flat no-lead package. The total charging solution is capable of delivering 45 W of power, with around 100 W/in2 (150mV/mm2) of power density, which two times more than competitive devices.

Additional resources

- Read the BQ25790 data sheet and theBQ25792 data sheet.

- Read the technical article, Universal and fast charging – a future trend for battery-powered applications.

Personalizing human body temperature with wearable temperature sensors

Of the four vital signs, temperature is most consistent from person to person and across time. We’ve all been taught that a normal body temperature is 37°C / 98.6°F. While most people are aware that this is an average, the assumption is that it’s an average across the population. What surprises many is the fact this is also an average in time, as our body temperature is in a perpetual state of flux due to physical activity, circadian rhythms, hormonal changes, weight, and even age. With recent events, there’s been a surge in interest for wearable temperature sensors to quickly warn the wearer of illness or infection, giving them time to self-isolate and reduce spreading a contagion further. For the first time, wearable temperature sensors can also provide key insights to a wearer’s thermal cycles, allowing algorithms that personalize what is normal for an individual, and detecting changes that could indicate an illness even before hitting the threshold for a low-grade fever (38oC / 100.4oF).

Looking for a discreet yet accurate wearable temp sensor?

|

Before diving into wearable tech, it’s important to understand where the benchmark of 37°C / 98.6°F came from. First proposed in 1851, German physician Carl Reinhold August Wunderlich analyzed temperature across millions of axillary measurements for 25,000 patients. Factoring in all the variability mentioned above, he proposed the normal range for a healthy adult to be 36.2°C-37.5°C, the defacto standard even today.

However, a recent study from Stanford University questions whether 37°C is still a valid measure of normal body temperature. Analyzing records set back to 1860, Stanford researchers showed that average body temperature has steadily decreased by 0.03°C per decade of birth (adjusted for factors such as gender, age, height and weight). So yes … you are now officially cooler than your parents.

With all this variability, let’s consider the implications. Take an 80-year-old man. Because of age, it would be pretty normal for his body temperature to be 36.2°C / 97.1°F. He wakes up at 6 a.m. and takes his temperature. Due to circadian rhythms, there could be a 0.5°C / 0.9°F drop in core temperature placing him at 35.6oC / 96.2oF. For him to even hit the standard threshold for a low-grade fever (38oC / 100.4o) his temperature would need to increase by 2.4oC / 4.2oF, which would be substantial. While a medical clinician would know to use a lower threshold, things could easily get more complicated if the man also had a thyroid issue elevating or lowering his temperature.

As wearable temperature sensors help enable the vision of the quantified self, the continuous tracking they provide could launch a new era of personalized medicine to more quickly identify deviations from what’s normal, indicating a potential infection, hormonal shift or disease.

Technology advancements, such as our TMP117 temperature sensor family, are enabling accurate, compact and low-power wearables for personal or clinical settings. The TMP117M sensor, designed specifically for medical applications, provides an accuracy of ±0.1°C from 30°C to 45°C, fully encompassing the American Society for Testing and Materials E1112 and European Standard 80601 specifications for electronic patient thermometers. Available in a 1-mm-by-1.5-mm package, the TMP117M sensor’s small thermal mass enables fast thermal response times and compact industrial designs to improve user comfort. Further enhancing the user experience is the minimal power consumption at less than 7 µW, enabling smaller batteries to optimize comfort and cost. The design illustrated in Figure 1 demonstrates the small form factor possible for wearable thermal monitoring applications.

Figure 1: Bluetooth® enabled thermal monitoring patch design

Connectivity options like Bluetooth® Low Energy unleash the true power of a wearable temperature sensor. As a parent of a child whose fever often exceeds 40°C (104°F) when she’s sick, it would be a huge relief to receive a notification on my smartphone that detects when her antipyretic medication is wearing off – before her temperature spikes to dangerous levels. Translating the same Bluetooth-enabled temperature solution to a hospital setting could bring a range of benefits, enabling patients to move more freely without being tethered to a patient monitor in their rooms, reducing the load on nursing staff to manually take temperature measurements, or improving triage in congested waiting rooms.

To accelerate wearable designs, be sure to check out the Bluetooth-Enabled High Accuracy Skin Temperature Measurement Flex PCB Patch Reference Design featuring the TMP117 with a CC2640R2F Bluetooth Low Energy wireless microcontroller. This design demonstrates how to construct a wearable temperature monitoring patch with an integrated antenna on a flexible substrate for maximum user comfort.

Additional resources:

- Decreasing human body temperature in the United States since the Industrial Revolution

- Is Older Colder or Colder Older? The Association of Age With Body Temperature in 18,630 Individuals

- Connect: BLE wearable patch demo

Connecting to Azure IoT using the DICE security standard with SimpleLink™ Wi-Fi®

Internet of Things (IoT) devices such as sensor nodes are often cost-sensitive and commonly utilize resource-constrained wireless microcontrollers (MCUs). These resource constraints, including limited on-chip memory and security features, may prevent the use of some security standards available in desktop or server environments. However, as they connect to the Internet and often reside in unsecured locations, IoT devices offer potential attack vectors for hackers. To provide a security standard that specifically addresses resource-constrained devices, the Trusted Computing Group, which creates open standards and specifications that enable more secure computing in devices ranging from IoT devices to cloud servers, has developed the Device Identity Composition Engine (DICE) standard. Microsoft assisted the development of the DICE standard and its Azure IoT Hub Device Provisioning Service supports DICE-enabled devices. However, since DICE-compliant devices use X.509 certificates and TLS, they can connect to any IoT service that supports them.

I’ll give you an overview of the benefits of DICE, how it works, and how to get started with DICE on the latest generation of TI’s SimpleLink Wi-Fi device family – the CC323X. I will point you to a SimpleLink Academy example that gives you a detailed step-by-step process of how to use DICE with SimpleLink W-Fi and how to then connect your device to Azure IoT.

How DICE works and its benefits

The DICE standard provides several potential security benefits, including a secure device identity, secure over-the-air (OTA) updates and remote software attestation. Remote software attestation enables a server to verify that a connecting device has indeed booted the correct image, as opposed to malware or an incorrect version. While SimpleLink Wi-Fi devices have always supported these capabilities, an established standard like DICE will simplify customer adoption of such security capabilities.

To meet the varied needs of embedded systems developers, the DICE standard comprises a set of guidelines that give both semiconductor providers and IoT device developers flexibility in implementing a DICE-compliant system. DICE employs industry-standard X.509 certificates. It defines certificate extensions to represent both the device identity and its associated firmware image. The IoT server side can use the DICE-generated certificate chain to perform standard Transport Layer Security (TLS) authentication, both to verify the device identity and to perform attestation of its firmware image. Because the certificate chain includes field values specifically tied to the IoT device’s firmware image, an OTA update requires a new certificate chain so that the IoT server can continue performing remote software attestation.

DICE and SimpleLink Wi-Fi

SimpleLink CC323X devices include the core software required to implement DICE. To prevent malware takeovers, only TI-signed software updates can modify the DICE core software. When DICE support is enabled, the DICE core software utilizes the unique key pair embedded into each SimpleLink device to generate the device identity and associated certificate chain. This operation requires the routing of a certificate signing request (CSR) to the appropriate certificate authority. The IoT device then uses this certificate chain for TLS authentication when joining the IoT network. The SimpleLink OTA operations are also DICE-enabled, automatically deleting the old certificate chain and generating a new one when the OTA operation replaces an existing IoT device firmware image with a new one.

You can learn more about DICE and SimpleLink Wi-Fi by viewing this SimpleLink Academy module that mimics the use of DICE in a production line process. This module will walk you through creating the DICE CSR, getting it signed using openSSL and securely storing the certificate in the SimpleLink secure file system. It then takes you through the steps needed to connect to Azure IoT with this certificate.

Accelerate your electric mask design

Overcoming design challenges for brushed-DC motors in smart sanitation systems

As the global population grows, so does the risk for carrying and transferring germs throughout our homes, hospitals, schools and places of work. Smart sanitation products such as automatic paper towel dispensers, soap dispensers, trash cans, and smart toilets and faucets can reduce the spread of germs in common areas.

It is possible to automate every movement or valve adjustment in smart sanitation products with an electric motor or solenoid, which enables hands-free operation and reduces the potential spreading of germs by contact. Brushed-DC motors and latching solenoids are popular in these products because of their low cost and ease of design. Engineers face many challenges when designing for these applications, however, related to:

- Position and speed control

- Stall detection

- System size

- Protection

- Battery life

In this article, we will look at how our brushed-DC motor and H-bridge drivers help address these design challenges.

Position and speed control

It is very helpful to be able to control the position and speed of a brushed-DC motor in smart sanitation products. For example, a paper towel dispenser needs to dispense a specific portion from the roll in order to not waste paper, while still providing a sufficient amount to users. In order to accomplish this, the system needs some form of feedback from the motor to know where the load is.

There are many ways to accomplish this, but one of the easiest is with integrated current sensing. Our brushed-DC motor drivers with integrated current sensing not only provide current feedback from the motor, but also remove the need for an external sense resistor. The DRV8876, for example, has integrated current sensing that uses a current mirror architecture to sense current in the motor windings and feeds this current information back to the microcontroller through the IPROPI pin. As shown in Figure 1, eliminating an external amplifier or sense resistor reduces component count, decreasing board size by at least 12% and lowering system cost.

Figure 1: The DRV8870 with an external shunt resistor vs. the DRV8871 with integrated current sensing

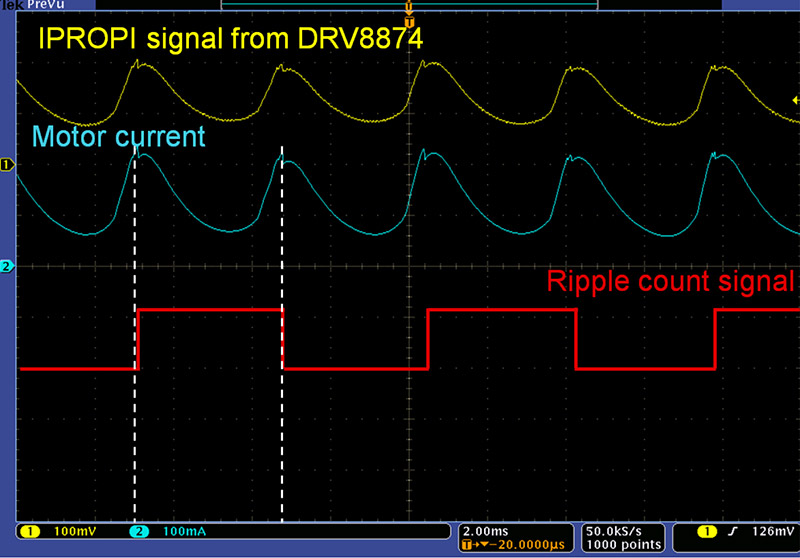

It’s also possible to leverage the motor current for sensorless position and speed detection, commonly referred to as ripple counting. As illustrated in Figure 2, ripples in the current are formed by the brushes in the motor making contact with the commutator during each rotation. The basic principle of ripple counting is to count the number of ripples in the current, which translates into rotations and thus the relative speed and position.

Figure 2: The IPROPI current feedback signal with ripples from brushed-DC motor commutation

Stall detection

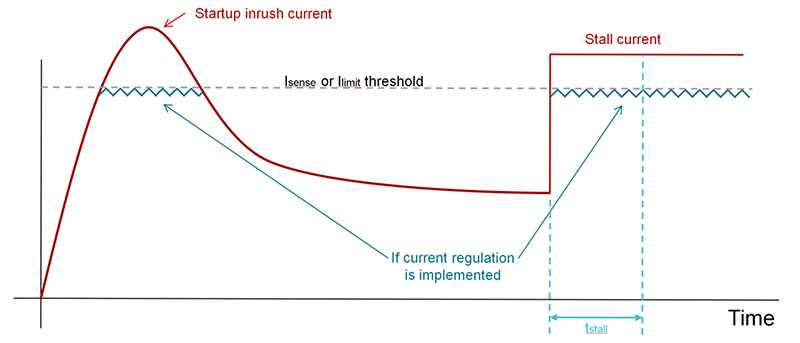

Now that I’ve shared a technique for monitoring speed and position, let’s discuss an effective way to detect end-positions or jams in motor movement, also known as stall events.

As illustrated in Figure 3, the motor startup creates a large inrush current, which then decreases to a lower level during continuous motor movement. Current then spikes once again when the load hits the end of travel, or if a jam in the system occurs from a large spike in applied torque.

Figure 3: Typical brushed-DC motor profile for systems with possible stall events

Using the IPROPI current-sense output, and the current-limit control on the DRV8873, DRV8874 and DRV8876, the microcontroller can sense these different current regions, detect the stall condition and stop driving the motor – saving energy and power without the need for any other external components.

Fitting motors and solenoids into small form factors

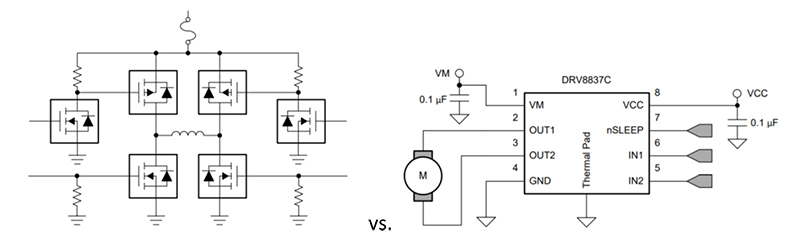

While many restrooms have automated systems, they still need to have an aesthetically pleasing form factor, or even be hidden from sight. This typically means that the system needs to be small, which does not leave much room for electronics.

A discrete brushed motor system not only needs to drive components and four individual power metal-oxide semiconductor field-effect transistors, or MOSFETs, but many systems include components for system protection. The move to an integrated motor-drive circuit can help significantly reduce board size and printed circuit board expenses, as well as the number of component sources, while integrating a full suite of protection circuitry such as thermal shutdown and overcurrent and undervoltage protection. As illustrated in Figure 4, the DRV8837C provides the entire drive and protection circuitry in a 4-mm2 package.

(a) (b)

Figure 4: Discrete H-bridge circuit (a); integrated motor driver H-bridge with the DRV8837C (b)

Automatic faucets often have two valves for mixing cold and hot water and can require two solenoids or brushed-DC motors, which in turn requires two H-bridges, taking up more space on the board. Devices like the DRV8847 are a good solution to integrate multiple motor drive systems into a single integrated circuit.

Battery-powered smart sanitation products and general design considerations

Since many smart sanitation products are battery powered, such as flushometers, and soap or paper towel dispensers, reducing the power consumption of the motor driver to extend battery life is crucial. Devices such as the DRV8837 will typically draw just 35 nA of current while waiting for a wake-up command from the microcontroller.

Using brushed-DC motor drivers from TI in smart sanitation system designs can help reduce board space, system cost, and consume less battery power, all while offering enhanced protection and functionality like stall, speed or position detection of the load being driven.

Additional resources

- Check out our brushed-DC motor driver portfolio to find the right motor driver for your smart sanitation system.

How zero-drift Hall-effect current sensors improve system accuracy, reduce form factor and simplify design

From autonomous vehicles to aircraft to factory floors, electrification and automation advancements are rapidly transforming our world. Systems that were previously manual, mechanical or hybrid are moving toward full automation and electrification thanks to increases in performance and reliability, and lower total lifetime cost. In fact, we are in the middle of the fourth industrial revolution focused on automation and smarter monitoring, also known as Industry 4.0. With the electrification revolution in full swing, high-voltage systems are becoming more prominent to enable higher efficiency and performance.

In systems that incorporate high-voltage domains, signal and power isolation can help protect people and critical circuits from high-voltage AC or DC power sources and loads. As systems are incorporating more electrical functionality, there are efforts to further shrink these systems to scale. This creates challenges related to the incorporation of increasingly dense form factors and pressure to achieve lower costs and design simplicity, while also maintaining high performance.

Current sensing is commonly used for overcurrent protection, monitoring and diagnostics, and closed-loop control in high-voltage systems, which often requires high accuracy for monitoring and controlling loads to maximize efficiency. Power factor correction circuits, for example, require the accurate sensing of AC currents in order to improve system efficiency as well as to monitor energy consumption. High-voltage motors also require precise in-line motor current sensing for accurate torque control of the motor. With many requirements depending on the specifics of each system, this article will focus on how to select the right current sensing technology for your high-voltage application.

Your three main options for measuring current in high-voltage applications are to use an isolated shunt-based current sensor, a closed-loop Hall-effect current sensor or an in-package Hall-effect current sensor.

As shown in Table 1, isolated shunt-based and closed-loop Hall-effect current sensors provide the highest levels of accuracy and isolation, but they’re more expensive and larger than in-package Hall-effect current sensors. So if ultra-high accuracy is your most important consideration, either of these approaches should meet your need.

If size and cost are critical to your design, in-package Hall-effect current sensors may be your best option. As explained in Table 1, they can enable high-voltage isolated measurements in a simple, small form factor that requires no external components, but they have historically drifted over time and temperature, which limits their accuracy.

We’ve solved this problem with the TMCS1100 zero-drift Hall-effect current sensor – the industry’s first in-package Hall-effect current sensor to eliminate this tradeoff. Its zero-drift architecture, real-time sensitivity compensation and reliable 3-kV isolation deliver consistent, accurate measurements over time and temperature in high-voltage systems.

| Isolated shunt-based current sensors | Closed-loop Hall-effect current sensors | In-package Hall-effect current sensors | |

Existing devices | TMCS1100 | |||

Solution size | – | – – | + + | + + |

External components needed | 1 to 3 | 2 to 5 | 0 | 0 |

Solution cost | – | – – | + + | + + |

Accuracy | + + | + + | – | + |

Offset and sensitivity drift | + + | + + + | – – | + |

Insulation Lifetime | + + | + + | – | + |

Table 1: Isolated current sensing technology comparison

The TMCS1100 provides <1% total error current measurement, and its zero-drift precision signal chain-architecture improves drift over temperature and eliminates the need for multi-point calibration. Additionally, the accuracy enables higher efficiency in systems for more accurate control, while minimizing complexity for any application that needs high-precision isolated current measurements, as shown in Figure 2. Further, the TMCS1100 provides a 600-V basic working isolation and 3-kV dielectric isolation between the current path and circuitry.

Figure 2: The TMCS1100 enables consistent, precise measurements over time and temperature

You can learn more about the advantages provided by this approach to magnetic-based current sensing, which include higher accuracy, lower drift and reliable 3-kV isolation, in the white paper, “Improving Performance in High-Voltage Systems with Zero-Drift Hall-Effect Current Sensing.”

Additional resources

- Read these application reports:

- Learn about the TMCS1100 current sensor.

Designing smart, energy-efficient air conditioning using TI mmWave occupancy sensors

How to efficiently drive 12-V and 24-V engine loads in automotive systems

An internal combustion engine (ICE) is a mechanical system that has been around since the 19th century (Figure 1). It’s amazing how it works, considering that it only takes fuel to generate thousands of horsepower and make a car go from 0 to 60 mph in under 3 seconds. But all good things must come to an end; stricter government standards such as Tier 3, Euro 6 and China 6a are requiring exported automobiles to reduce emissions to minimal levels. In response, the automotive industry is electrifying (literally) to create electric vehicles (EVs) and hybrid electric vehicles (HEVs) that have electric subsystems inside the conventional ICE.

Figure 1: A conventional ICE

View our Automotive 12-V to 24-V Engine Load Interface Reference Design.

Ready to design? |

But wait, how can you electrify an engine?

Well obviously, you can’t electrify the combustion process itself. However, the rest of the engine platform has a myriad of engine sensors to continuously monitor system parameters such as temperature, position and exhaust (Figure 2). The sensors send data to the engine control unit (ECU) to calculate the engine’s current performance and compare it to its desired performance. Solenoids, relays and DC motors are controlled by the ECU, to open or close valves and correct the amount of fluid flowing through the subsystem. This “corrects” the system performance, and the closed-loop cycle continues as long as the engine is running.

Figure 2: Block diagram overview of an engine platform design, including input sensors and output load switches (highlighted in red) that interface with the ECU

By using electric sensors and engine loads powered from the 12-V or 24-V battery, the engine reduces dramatically in size and limits emissions from the exhaust while continuing to utilize combustion as the main source of engine power. The main caveat to electrification in automotive applications is ensuring that all electrical components are automotive-qualified and have temperature grade 1 or 0. This allows for engineers to design systems that are compliant with International Organization for Standardization standards (ISO 26262) and be Automotive Safety Integrity Level (ASIL) certified for functional safety.

How can you drive these engine loads?

Solenoids and DC motors use a power metal-oxide semiconductor field-effect transistor (MOSFET) stage to drive inductive loads, with configurability for added protection. N-type MOSFETs can drive up to tens of amps when actuated, and the number of MOSFETs you’ll need depends on what configuration you want to drive your load.

Solenoids can be driven with a high-side (HS), low-side (LS), or push-pull configuration (Figure 3). These configurations provide trade-offs on their implementation, number of components needed and protection(s) offered to the power stage.

Figure 3: Trade-offs of various solenoid driver configurations

To efficiently drive solenoids, you can use pulse-width modulation (PWM) signals from the gate driver to regulate current. It takes a larger amount of current to actuate the solenoid, but only a smaller amount of current to hold it in place. By switching to a lower PWM duty cycle once the solenoid is on, less power will dissipate through the solenoid windings to lower thermals and increase the longevity of the load.

An automotive device like the DRV8343-Q1 can drive up to six independent loads using independent MOSFET mode. It is rated for up to 60 V, integrates three current shunt amplifiers, and includes protection features and diagnostics for the implemented configurations. If you’re looking for a more integrated automotive solution, the DRV8876-Q1, DRV8874-Q1, and DRV8873-Q1 can each drive up to two independent solenoids and include integrated MOSFETs and current regulation. These devices are rated up to 37 V and have varying peak current and total RDS(on) values to support a wide range of solenoid currents.

Both solutions (Figure 4) are Automotive Electronics Council (AEC)-Q100 qualified for automotive applications and temperature grade 1 (-40°C to 125°C ambient).

Figure 4: Driving solenoids using the DRV8343-Q1 or DRV887x-Q1

If you’re ready to jump right into a design, check out our Automotive 12-V to 24-V Engine Load Interface Reference Design (Figure 5). This solution is rated for both 12-V and 24-V automotive systems and drives engine loads in four distinct configurations (HS driver, LS driver, HS + LS driver, and push-pull driver) with a microcontroller and the DRV8343-Q1 gate driver. The design also includes reverse polarity protection, integrates protection and diagnostic features, and is less than 16 square inches in size.

Figure 5: Engine load interface solution for 12-V and 24-V automotive systems

Now that I have shared the various options TI offers to interface with engine loads, I should mention that there is also plenty of content and knowledge available on TI.com to assist you in your engine platform printed circuit board design. Although ICEs are mechanically complex, they don’t have to be electrically!

What features are most important for your engine platform design? Please share in the comments below so that we can highlight these in our devices. Make sure to check out our Gasoline and Diesel Engine platform page for products and designs to make your engine platform design the way you want it.

Additional resources

- Read the application reports, “Using DRV to Drive Solenoids – DRV8876/DRV8702-Q1/DRV8343-Q1” and “Automotive Reverse Polarity Protection.”

- Download the DRV8343-Q1 and DRV8873-Q1 data sheets.

- Watch the YouTube video “Motor Drivers in Engine Control Units” from Texas Instruments

Ease power-supply design for USB PD applications with buck-boost converters

USB technology has evolved – from a data interface capable of supplying limited power to a primary power source with an interactive data interface. Today, many devices charge or get their power from USB ports contained in laptops, cars, aircrafts or even wall sockets.

Because of its compact size and ability to both deliver power and transfer data, USB Power Delivery (PD) has become a ubiquitous power socket for many small devices such as cellphones, laptops and other handheld devices, as shown in Figure 1.

Figure 1: Example laptop docking station with USB PD

USB PD specifications define how USB devices can negotiate for more current and/or higher or lower voltages over a USB cable, using the USB Type-C CC wire as the communications channel. USB PD specifications allow devices with greater power requirements to get the power they require to operate from the bus voltage (VBUS) while negotiating with external power sources.

To facilitate optimum charging, a USB PD charger must use one of these two mechanisms:

- A list of fixed voltages, each with its own maximum current.

- A list of programmable voltage ranges, each with a maximum current (programmable power supply), where the device will request a voltage (in 20-mV increments) that is within the specified range and within the maximum current allowance.

In this article, I’ll show you how to optimize USB PD charging capabilities by adding a buck-boost converter to your design.

Shrinking your overall design footprint while delivering maximum charging efficiency

Synchronous buck-boost converters can convert a battery voltage or adapter voltage into power-supply rails. TI’s TPS55288, for example, can adjust the output power range from around 10 W to 100 W based on the input voltage. Through the I2C interface, the output voltage of the TPS55288 is programmable from 0.8 V to 21.26 V with a 20-mV step. The default output voltage is 5 V when the device is enabled, and can be used in a docking station, car charger, wireless charger or PC applications.

Figure 2 shows the solution size of the TPS55288 400-kHz evaluation module board. When working in boost mode, the TPS55288 can deliver 100 W from a 9-V input with a 400-kHz operating frequency.

Figure 2: 400-kHz EVM board solution size for the TPS55288

Figure 3 shows the conversion efficiency of the TPS55288 400-kHz EVM board in forced pulse-width modulation (FPWM) mode. When VIN≥ 12 V, the conversion efficiency is higher than 95% at the 100-W output condition.

Figure 3: Efficiency vs. output current (fSW = 400 kHz, VOUT = 20 V)

Figure 4 shows the solution size of the TPS55288 2-MHz EVM board. When working in boost mode, the TPS55288 can deliver 60 W from a 12-V input with a 2-MHz operating frequency.

Figure 4: 2-MHz EVM board solution size for the TPS55288

Figure 5 shows the conversion efficiency of the TPS55288 2-MHz EVM board in FPWM mode. When VIN≥ 12 V, the conversion efficiency is higher than 90% at the 60-W output condition.

Figure 5: Efficiency vs. output current (fSW = 2 MHz, VOUT = 20 V)

Improving thermal performance

Good thermal performance means higher reliability and longer lifetime for a product. Figure 6 is a thermal image of the TPS55288 400-kHz EVM board at 20-V/3-A and 20-V/5-A load conditions, respectively. The TPS55288 has only a moderate 40°C temperature rise at a 20-V/3-A load. Even at 100 W output power without a heat sink or thermal pad, the maximum temperature on the TPS55288 is only 86.4°C, much lower than the 150°C limit.

Figure 6: Thermal performance (fSW = 400 kHz)

Achieving low EMI

A key design challenge for the power supply design is passing the electromagnetic interference (EMI) test. Circuits that fail the EMI test repeatedly often require round-the-clock efforts in the lab to fix the problem and avoid product launch delays. The TPS55288 buck-boost converter can achieve very good EMI performance. With frequency dithering function and by optimizing the placement and routing, the device can pass CISPR25 level 5 conducted emission and radiated emission limits, which are very strict.

Figures 7 and 8 show the EMI performance of the TPS55288 buck-boost converter under 400-kHz and 2-MHz operating frequencies, respectively. The test result passes the CISPR 25 level 5 limit with higher than 6 dB margin.

Figure 7: Conducted and radiated EMI results under fSW = 400 kHz (12 VIN, 15 VOUT/3 A)

Figure 8: Conducted and radiated EMI results under fSW = 2 MHz (12 VIN, 15 VOUT/3 A)

Benefits of a programmable output current-limit function

Besides high efficiency, small solution size and low EMI, other features make the TPS55288 a good fit for USB PD applications.

The TPS55288 buck-boost converter can program the output current-limit point, which helps the circuit easily pass the UL 100-W maximum output power test. You can use the 03H internal register to set the response delay time if the output current exceeds the set output current limit. This enables the TPS55288 to output high current in a relatively short time, which helps the circuit meet the peak current requirement in Section 6.4.1 of the USB PD specification.

How are you designing with the TPS55288? Please add a comment below on how you’re using the device, and how it’s shortening your design time.

Additional resources

Read these application reports:

4 audio trends transforming the automotive industry

By Krunal Maniar

The automotive industry is focused on creating a comfortable driving experience – but without compromising fuel efficiency or manufacturing costs. Original equipment manufacturers (OEMs) are refreshing their audio system architectures frequently to enhance the user experience and ensure safety by incorporating new audio technologies.

Techniques using microphones, amplifiers, loudspeakers and advanced digital signal processing can help enable background noise reduction, clearer voice communication between passengers, and emergency and high-fidelity hands-free voice calling. These are the four audio trends transforming automotive audio design.

Trend No. 1: Active noise cancellation systems

As is already well established in the consumer electronics industry, OEMs are increasingly adopting active noise cancellation. Conventional noise-cancellation techniques such as passive insulation and specialized tires make vehicles heavier and reduce fuel efficiency. Active noise cancellation methods can achieve the same benefits, while weighing less compared to passive insulation methods and without affecting fuel efficiency.

An active noise cancellation system works by strategically placing between two and six microphones throughout the interior cabin of a vehicle; see Figure 1. These microphones measure interior noise and transmit audio data to an audio subsystem that in turn puts out an anti-audio signal to built-in loudspeakers. Since these are the same loudspeakers used for audio playback applications, the addition of an active noise cancellation system comes at a relatively low additional cost.

Figure 1: An active noise cancellation system uses microphones and loudspeakers to reduce in-cabin noise

An active noise cancellation system for entry-level cars uses two to four microphones, whereas high-end cars use as many as eight microphones.

Trend No. 2: In-cabin communication systems

Also called in-vehicle communication systems or in-car communications systems, in-cabin communication is just what it sounds like: it enables clear communication among occupants while inside the car. An in-cabin communication system works by strategically placing two to eight microphones to pick up the speech of each passenger, adaptively enhancing the speech of the person talking, reducing unwanted noise, and then playing the speech on the car audio loudspeaker system.

Keep up with the challenges of today's microphone-based automotive applications

Learn more about TI's new PCM6260-Q1 automotive audio ADC with integrated programmable mic bias, boost and input diagnostics. |

Trend No. 3: Emergency calling (eCall) systems and hands-free voice systems

An eCall system typically has one or two microphones for direct audio communication between the car and local emergency services in case of an emergency. A connectivity module digitizes and transmits the microphone signal to emergency operators. The speech from the emergency operator is played back on dedicated loudspeakers inside the car.

Like eCall systems, hands-free voice systems have between one and eight microphones, or an array of beamforming microphones, to enable clear voice calls and voice commands.

Trend No. 4: Centralized audio hubs

Looking ahead to future implementations, many OEMs are considering a centralized audio hub (shown in Figure 2) that would aggregate active noise cancellation, in-cabin communication, eCall and hands-free microphone inputs, digitize these audio signals, and send the digitized signal to each respective audio subsystem for further processing.

Figure 2: A centralized audio hub module

As trends in active noise cancellation, in-cabin communication and hands-free beamforming pick up, a centralized audio hub will reduce the amount of microphone routing required, the implementation complexity, and the cost associated with microphone cables.

To accommodate the short- and long-term vision of OEMs and Tier 1 manufacturers, Texas Instruments developed the PCM6260-Q1 multichannel audio analog-to-digital converter family; Table 1 lists the various devices in the family.

Device | No. of inputs | Boost converter | Microphone bias | Microphone diagnostics |

PCM6240-Q1 | Four analog | ✓ | ✓ | ✓ |

PCM6260-Q1 | Six analog | ✓ | ✓ | ✓ |

PCM6340-Q1 | Four analog | x | ✓ | ✓ |

PCM6360-Q1 | Six analog | x | ✓ | ✓ |

Table 1: The PCM6260-Q1 device family

These devices support analog and digital microphone and line inputs and integrate a programmable high-voltage microphone bias and input fault diagnostics. They provide a flexible digital filtering scheme with linear-phase and low-latency filters, multiple second-order infinite impulse response filters per channel, and high-pass filters. The PCM6260-Q1 family supports a flexible data output and control interface, allowing several devices to use the same output data and control the interface bus. The devices have general-purpose inputs/outputs, fine phase and gain calibration schemes, and a digital mixer and summer to optimize system performance.

The adoption of these new audio technologies in cars – while requiring major architecture changes – promise to bring a richer driving and in-car communication experience.

Additional resources

- Read more about automotive active noise cancellation techniques in Electronic Products.

- Learn more about the PCM6260-Q1 family of automotive audio ADCs in the app note, Scalable Automotive Audio Solutions Using the PCM6xx0-Q1 Family of Products.

- Learn how to use PCM6260-Q1 in microphone and line-input applications in the app note, PCM6xx0-Q1 Use-Case Scenarios in Automotive Audio Applications.